Precision machining is a kind of machining technique that produces elements using gadget equipment which are controlled by computers. To create merchandise with tight tolerances, high complexity, or, excessive-velocity machining is used. An educated precision machinist operator or maybe excessive-pace robotics may also perform precision machining.

By way of offering extremely good, unique, and specialized machined additives and elements, cnc precision machining services suppliers play a tremendous function in the manufacturing commercial enterprise. Those corporations produce components with unusual tolerances and difficult geometries, consistently use pinnacle-notch CNC gadgets, and have knowledgeable employees. CNC precision machining offerings can fulfill your necessities whether or not you work in the aerospace, automotive, scientific, or some other industry that requires specific components.

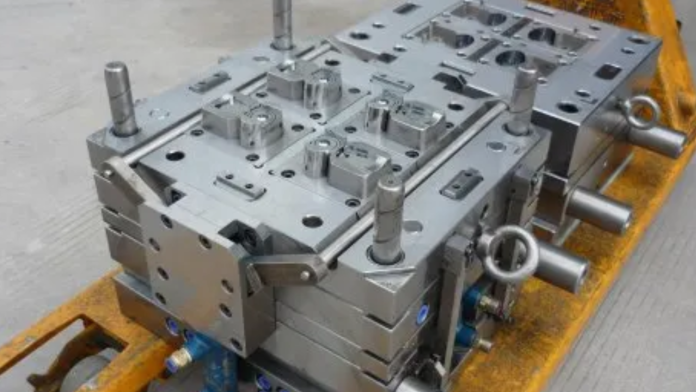

What Are Components For Precision Machines?

An amazing deal of the gadgets we use every day incorporate elements and additives that may be produced thanks to precision machining. Moreover, additives produced with unique equipment have great accuracy. Without the need for bodily paintings, these components also can reduce substances such as metal, aluminum, copper, and plastics.

Kinds of Materials Are Appropriate For Precision Machining

The material to select is determined via the unique software and the preferred traits of the completed product. The subsequent listing of standard materials for precision machining is accompanied by records on each one:

Aluminum

Aluminum, which is regarded as distinctive in phrases of production, is arguably the maximum famous cloth for CNC milling. Aluminum is a better cloth for CNC machining because it can be machined more quickly than other substances. Aluminum is frequently used to make food boxes, bicycle frames, vehicle components, and aviation additives due to the fact its miles light-weight, non-magnetic, corrosion-resistant, and low priced.

Stainless Steel

The majority of stains and rust can’t penetrate stainless-steel alloys. The material, which is valued for its sturdiness and corrosion resistance, is utilized for the whole lot from surgical systems to electrical devices. Because of its high adaptability, relative lightness, and sturdiness, stainless steel is used in a wide variety of sectors.

Carbon Steel

Every other common fabric selected for CNC machining is carbon steel. You could select from a selection of formulas relying on the needs of your software. Due to its power, protection, prolonged shelf lifestyles, accessibility, and environmental friendliness, the fabric is frequently used for CNC machining.

Brass

Brass is used to create complex pieces that want advanced characteristics because it is widely known to be one of the best and maximum low-priced substances to hire with precision machining services. Brass is used to make a selection of products which includes fittings, patron items, digital hardware and contacts, scientific devices, and business goods because of its ease of machining, smoothness, and clean end.

Titanium & Magnesium

Due to its heat and corrosion resistance, titanium is a superb alternative for plenty of commercial packages. Titanium is frequently used to create rings, aircraft elements, and clinical implants because it’s proof against salt and water. Magnesium is the lightest structural metallic this is often hired by groups that offer precision machining offerings. Magnesium has brilliant machinability and gives energy and durability, making it suitable to be used in a variety of commercial programs.

Monel

Monel elements that have been CNC-machined are in high call for. Its miles often employed in programs that need higher strengths and are exposed to corrosive situations. Because of the difficult tooling requirements and a small quantity of CNC machining facilities specializing in Monel machining.

Inconel

It’s a super alloy product of nickel that has emerged as pretty famous in recent years due to some of its positive traits. Inconel components are appropriate for settings where aqueous corrosion or oxidation may additionally occur. Moreover, it might be ideal for making use of in which the additives can be heated and below severe strain.

Bottom Lines

That allows you to maximize value without sacrificing dimensional accuracy, precision machining is the fine option. That is why the use of the technique to create prototypes or mass-produce items has become a fashionable practice in manufacturing. Get in contact with 3ERP if you require honest precision machining services, and you will acquire a fee within 24 hours.