Molds and mold making are critical to the injection molding technique, as they determine the pleasantness, precision, and performance of plastic element production. 3ERP is a professional mold maker china, maximum styles of manufacturing strategies, inclusive of plastic injection molding, metal injection molding, excessive pressure die casting, steel casting, profile extrusion, and sheet metal.

The mold shapes the very last product, ensuring it meets layout specs and purposeful requirements. They’re important for attaining tight tolerances, complicated geometries, and high production volumes, making them fundamental to industries like automotive, purchaser goods, and scientific devices in which precision and reliability are paramount.

Growing splendid injection molds is a complicated process requiring interest in diverse technical details and fine practices. Adopting some great practices allows for handling prices, reducing cycle times, and achieving excessive manufacturing standards.

Major Considerable Tips When Making Molds

Every tip addresses a vital thing of the mold-making process, contributing to the general success and durability of the mold. Right here are some key tips to keep in mind while making molds, making sure a hit consequences and efficient production:

Invest in Comprehensive Design Analysis

Investing time and resources into a thorough design analysis can shop good-sized costs and effort afterward. Use advanced CAD software and behavior mold flow evaluation to simulate the injection method, predicting how the plastic will fill the mold. Recollect the parts’s geometry, wall thickness, and draft angles to facilitate ejection and reduce defects. Collaborate with design and engineering teams to validate the mold design, ensuring it aligns with manufacturing capabilities and element specifications. Right layout evaluation ensures the mold will produce first-rate parts consistently and successfully.

Choose the Right Material

Selecting suitable materials for each mold and the parts being produced is essential. For the mold itself, materials like device steels (P20, H13) or aluminum are usually used. Tool metallic provides sturdiness and is appropriate for high-quantity manufacturing, whilst aluminum is good for prototyping or lower-extent runs due to its ease of machining and lower cost. The material choice has to additionally keep in mind elements consisting of thermal conductivity, wear resistance, and machinability. Proper material choice contributes to mold sturdiness and overall performance.

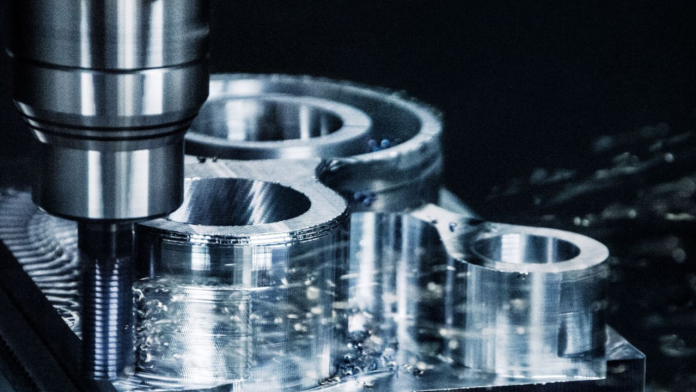

Focus on Precision Machining

Precision in machining mold parts directly influences the excellence of the final parts. Make use of superior CNC machines, EDM (Electrical Discharge Machining), and other high-precision tools to manufacture the mold as it should be. Make sure that machining tolerances are tight, mainly in crucial regions consisting of the mold hollow space and core, cooling channels, and ejection mechanisms. Precision machining no longer complements the part nice but also reduces the likelihood of defects and rework.

Optimize Cooling System Design

Efficient cooling is essential for lowering cycle instances and ensuring the steady part best. An optimized cooling machine allows managing thermal stresses and minimizes problems like warping or internal stresses. Use conformal cooling channels that follow the mold’s contours, improving cooling performance and uniformity. Well-sized and positioned cooling channels can considerably improve mold overall performance, leading to faster production cycles and better-fine parts.

Implement a Rigorous Maintenance Schedule

Regular maintenance is crucial to maintain molds in the finest condition and amplify their lifespan. Increase a preservation schedule that consists of habitual inspections, cleaning, and lubrication of shifting elements. Update worn additives which include ejector pins and seals earlier than they cause defects or operational issues. Use facts monitoring systems to music mold overall performance and discover capacity issues early. A nicely-maintained mold guarantees steady manufacturing first-rate and minimizes luxurious maintenance and downtime.

Final Remarks

Effective mold making, which entails design, material choice, and precision machining, impacts the sturdiness and performance of the mold, impacting production fees and component high-quality. Amazing molds enable speedy, steady, and powerful manufacturing, minimizing defects and waste.